United States

Canada

- Europe

Netherlands

Germany

- Africa

- Rest of World

Keeping your pump in shape will help reduce costs and boost profits!

Cut fuel consumption, reduce replacement parts costs and minimize pumping time on every job!

A PUMP THAT LETS YOU DOWN when you need it most causes obvious losses of time and money. Not so obvious, but every bit as costly, are losses you can incur with pumps that operate at less-than-peak efficiency. A pump laboring under the handicap of a suction line air leak, a corroded discharge line or a clogged impeller uses excessive energy, takes longer than necessary to do the job, and subjects parts to undue stress, causing premature failure.

HOW HIGH CAN THE LOSSES RUN?

A 6-inch gasoline-driven, self-priming centrifugal pump operating at 25% less than peak efficiency through an eight-hour day uses approximately 8.8 gallons more fuel than a pump operating efficiently. At $2.00 per gallon over a 40-hour week that’s $80.00 per week LOST! And that figure doesn’t include additional service costs!

Multiply these possible hidden losses by the number of pumps you have in operation and you see why it pays to keep your pumps in top working order.

Gorman-Rupp wants to keep your pumps efficient.

If you already own Gorman-Rupp pumps, you know how easy they are to service, so there is really no reason to let them deliver less than their best.

But even if you don’t own Gorman-Rupp pumps, you’ll find our 9-point checklist helpful because today every penny of profit counts, and we want your pumps to work as efficiently as possible.

CENTRIFUGAL PUMPS

Indications that your pump isn’t operating at peak efficiency may not be dramatic, but they’re easily recognized. Look for these signs of inefficiency:

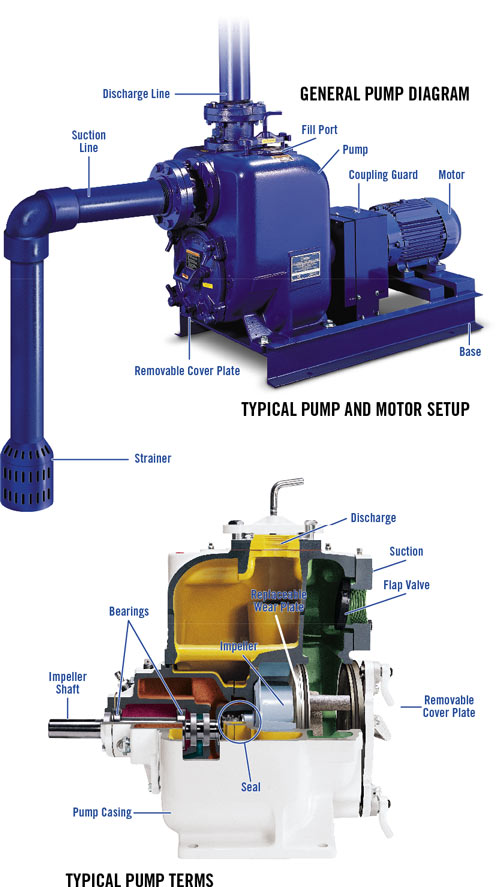

There is a noticeable difference in pump flow. Has the discharge flow visibly decreased? Is it taking your pump longer to do the same job than it used to? The slow-up might be caused by a collapsed suction hose lining, a leaking gasket, a plugged suction line, or a damaged or worn impeller or wear plate.

Your pump isn’t repriming as rapidly as it once did. Most commonly, slower reprime can be attributed to excessive face clearance. If this is not the cause of your slowdown, check the following: Is the seal leaking? Are all hardware at gaskets tight? Is the suction check valve sealing properly? Is the cutwater section of the volute badly worn? Is the recirculating port clogged?

Your pump is making excessive noise. Does it sound like a bunch of marbles rattling in a can? This may be an indication of cavitation and could be caused by a suction lift that’s too high, a suction hose that’s too long or plugged or that has a collapsed lining, a clogged strainer, a combination of any of these, or perhaps a problem on the discharge side of the pump.

Failing bearings can also cause excessive noise.

Your pump is clogging frequently. The suction check valve may be clogged, the strainer may be too large or too small, face clearance could be too wide, or the strainer may be stuck in mud, plugging the suction side.

Your pump is overheating. Very likely the flow of liquid into or out of the pump is being restricted. Improper impeller clearance could be slowing repriming, or the suction strainer may be clogged.

USE THIS CHECKLIST TO IMPROVE PUMP PERFORMANCE …AND PROFITS

Although this list is not a complete guide to pump inspection and service, it does cover the more common conditions that can impair pump efficiency. Keep in mind that excessive wear could also be the cause of any of the problems in the above paragraphs.

SUCTION LINE

PUMP

DISCHARGE LINE

A WORD ABOUT submersible and diaphragm pumps

If your submersible pump is operating at a reduced capacity, it could be caused by a worn impeller, excessive impeller clearance, low or incorrect voltage, or it could be running backward. A discharge head that’s too high, a clogged or kinked hose, or a clogged strainer could also be responsible for reduced flow. Use an amp meter and volt meter to determine if the pump is getting the proper power it needs to operate efficiently. Normal amp readings are provided in the manual accompanying your pump.

If your diaphragm pump isn’t pumping as it should, check the diaphragm, suction and discharge check valve flappers and seats, and replace any worn parts. Check suction hose fittings for leaks, and check the plunger rod for proper adjustment.